We Specialize in Manufacturing

Solenoid Systems has over 30 years of experience manufacturing custom solenoids, solenoid valves and solenoid systems in the automotive, off-highway, industrial, aerospace and medical markets – and everything in between.

Our Manufacturing Expertise include:

- Serial Production (high and low volume)

- Coil Winding

- Wire Termination (Resistance Welding)

- Coil Overmolding

- Low Pressure Molding

- Manufacturing Process Design

Our Manufacturing Processes & Services

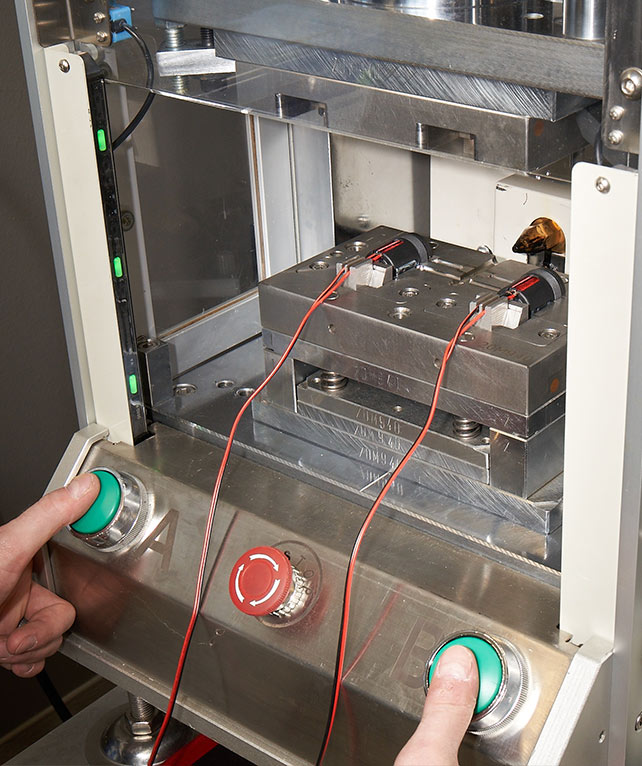

Serial Production

Solenoid Systems leverages over 30 years of manufacturing experience in Coil Winding, Resistance Welding, Overmolding and Assembly Processes. Our U.S. based facility supports low to high volume production, ranging from manual to highly automated processes.

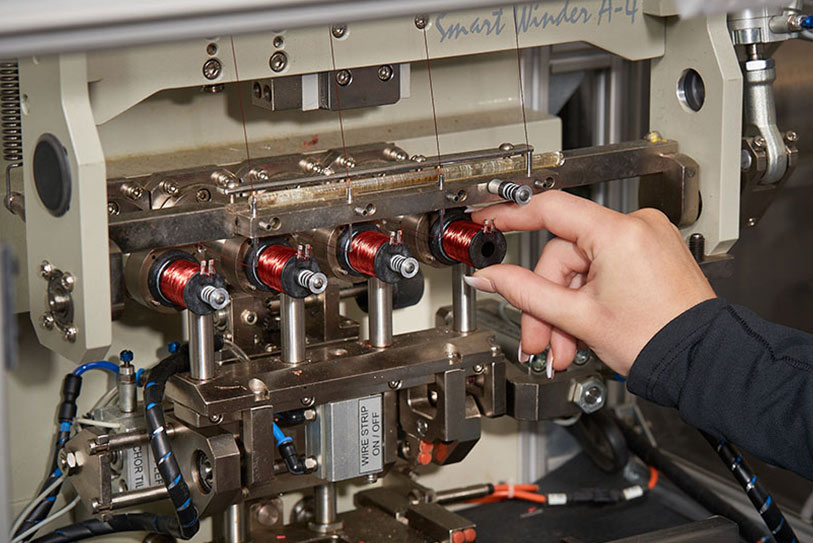

Coil Winding

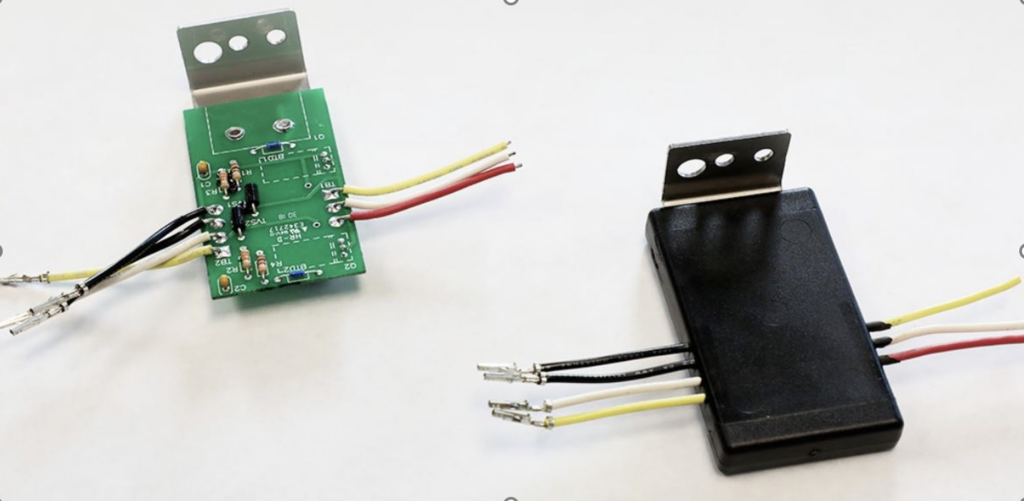

Coil Overmolding

Solenoid Systems uses a a Low Pressure Molding Process to Overmold our coils. The Low Pressure Molding process encapsulates parts safely providing waterproofing and protection against temperature extremes, harsh chemicals, shock and vibration.

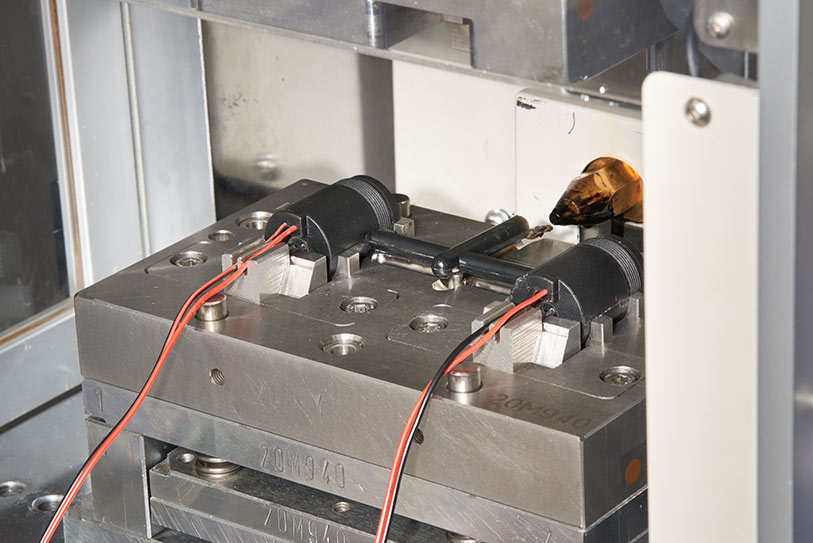

Wire Termination - Resistance Welding

Resistance Welding Magnet Wire to Terminals or Lead Wires has many advantages over soldering:

- Produces Stronger joints

- Higher Temperature rated Magnet

- Can process Higher Temperature Magnet Wire Insulation

- Wire Insulations can be used

- Repeatable, does not rely on an operator’s skill

- Quality Control, weld parameters can be monitored to verify a quality joint

- Can be used on a variety of materials

Low Pressure Molding

Solenoid Systems provides short and long-term overmolding services and contract manufacturing.

Low Pressure Molding encapsulates parts safely, providing waterproofing and protection similar to traditional technologies such as potting, sealing or conformal coating but with faster processing times at a fraction of the cost.